This is your website preview.

Currently it only shows your basic business info. Start adding relevant business details such as description, images and products or services to gain your customers attention by using Boost 360 android app / iOS App / web portal.

Manufacturing test

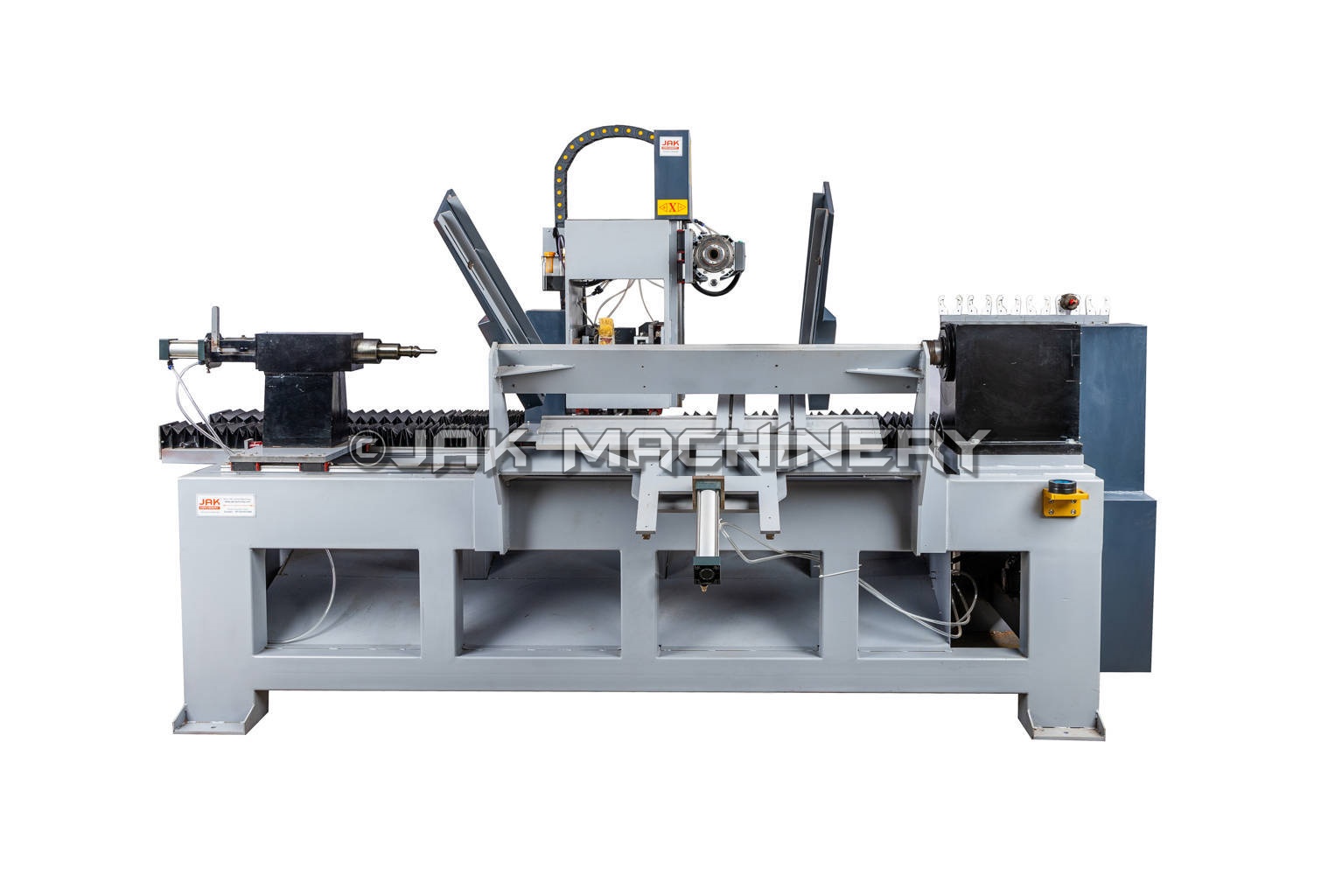

CNC Mill Band Saw (Autofeed)

VIEW DETAILS

5 Axis Multi(8) Head CNC Lathe Machine

VIEW DETAILS

5 Axis Multi(4) Head Double Station

VIEW DETAILS

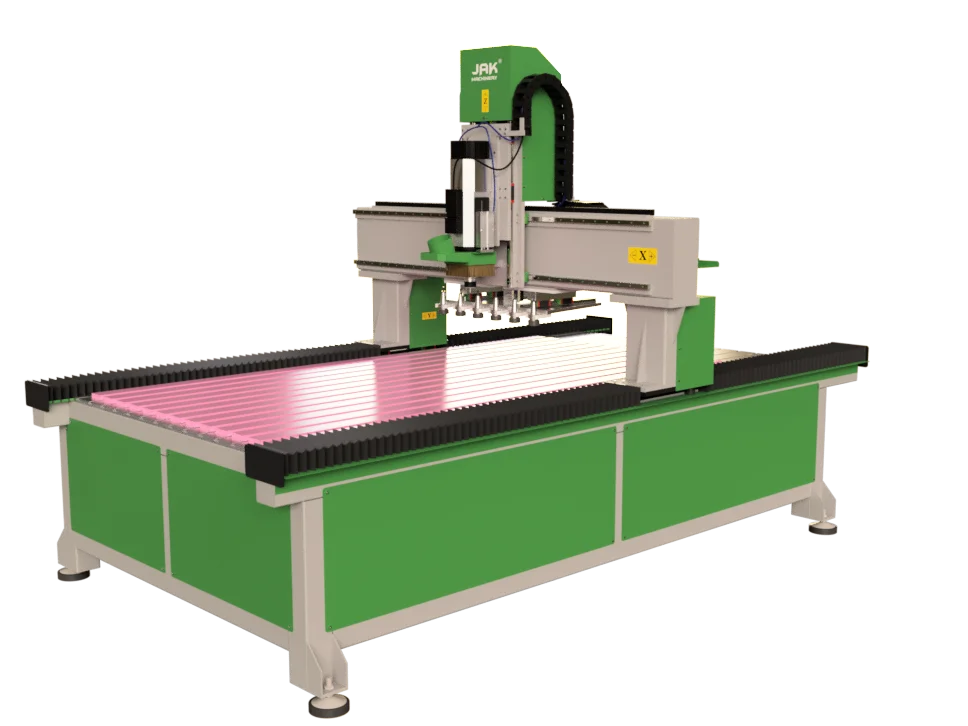

ATC Advance Router

VIEW DETAILS

Advance Router

VIEW DETAILS

Tenon and Mortise Machine

VIEW DETAILS

4 Axis CNC Wood Lathe Machine

VIEW DETAILS

MTC Router

VIEW DETAILS

ATC Router

VIEW DETAILS

CNC 5 Axis ATC Wood Lathe Machine

VIEW DETAILS

Filter using tags

5 AXIS WOOD LATH5 AXIS MACHINEWOOD CARVINGCNC ROUTERrouter with lathrouter with rotarywood carvingchair table leg manufacturingcnc routermanual tool changedoor profile cuttingAdvance routerDOOR CARVINGCNC WOOD CARVING